DSP stocks over 1,000 custom mold sizes, allowing us to quickly meet unique specifications and deliver tailored plast...

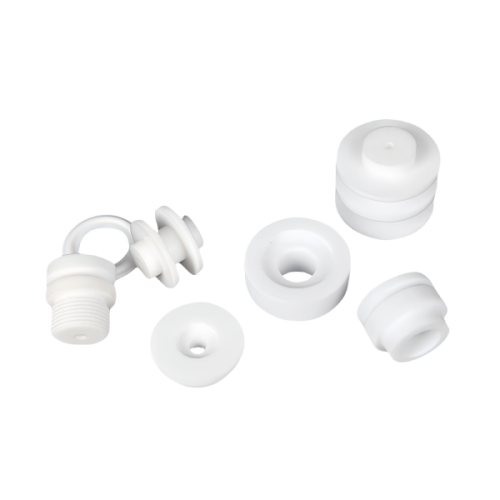

PTFE Insulators

DSP currently housed in a modern, 30,00 sq. ft., facility in Hebei, Northwest of Beifotai town , with over 10 years experience, DSP serve high quality precision Modified Teflon ® PTFE, machined PTFE, PEEK, PA6G, POMC, ABS plastics parts on time & at our lowest cost.

Our center own 48 CNC machines and compress mold machines, stocking over 1000 custom mold size.

DSP currently housed in a modern, 30,00 sq. ft., facility in Hebei,Northwest of Beifotai town ,With over 10 years experience.

Click here to watching the videoPTFE o-rings,Backup rings,Flat rings, Lantern rings and ptfe disc are widely used for static sealing in semiconductor, chemical, automotive, food and other fields. PTFE((Polytetrafluoroethylene ) compression molding comes from a powdered resin in a closed die set at ambient temperature by applying high pressure to create a preformed shape. The preform is removed from the molding die and free sintered (heated) in programmable ovens to fuse the molecules into a solid form.Certain fillers and combinations of fillers can enhance the wear, friction, compressive strength, such as: · Glass fiber Most widely used filler in various percentages (5%, 10%, 15% and 25%) Improves creep resistance, both at low and high temperatures Chemically stable (except for strong alkalis and hydrofluoric acid (HF) Little effect on the electrical properties of PTFE, and improves wear and friction behavior · Carbon fiber Carbon is usually added by weight between 10% and 35%. Increased hardness Increased thermal conductivity Adds to creep resistance Excellent wear properties when combined with graphite; carbon/graphite compounds preferred for non-lubricated piston rings Softer carbon additive lowers tool wear during machining, allowing machining to closer tolerances Carbon containing compounds have some electrical conductivity and are therefore anti-static · Graphite Used between 5% and 25%, graphite allows improving the coefficient of friction properties. It’s chemically inert and has high load-carrying abilities for high-speed contact purposes. Often it is added to other types of PTFE, but it helps enhance strength, wear properties, and deformation under load. · Bronze High percentage of bronze powder (40-80%) yields high thermal conductivity and better creep resistance Often used in hydraulic systems, particularly superb as linear bearings, e.g. slides, gibs, guide ways Not suited for electrical applications Bronze is attacked by certain chemicals

We’ve relied on DSP for over 5 years for high-quality PTFE and machined parts. Their precision and on-time delivery are unmatched, making them a trusted partner in our projects.

DSP consistently provides top-notch PEEK and POMC parts. Their expertise and fast turnaround make them an essential part of our supply chain.

DSP’s quality and reliability in supplying custom plastic parts—on time and at competitive prices—make them our go-to supplier for critical components.

Nov-07-2024

Nov-07-2024

Admin

Admin

DSP stocks over 1,000 custom mold sizes, allowing us to quickly meet unique specifications and deliver tailored plast...

Nov-07-2024

Nov-07-2024

Admin

Admin

With 10+ years of expertise, we deliver precision parts in Modified Teflon® PTFE, PEEK, and more, ensuring reliab...

Nov-07-2024

Nov-07-2024

Admin

Admin

DSP supplies the oil and gas industry with precision-engineered PTFE and PEEK components like O-rings, valve seats, a...