Available

Available

Our equipment covers CNC (computer numerical control) milling centers, CNC turning,CNC cutting,CNC routing, standard milling plastic machines, and other machinery to meet your needs.

Our equipment covers CNC (computer numerical control) milling centers, CNC turning,CNC cutting,CNC routing, standard milling plastic machines, and other machinery to meet your needs.

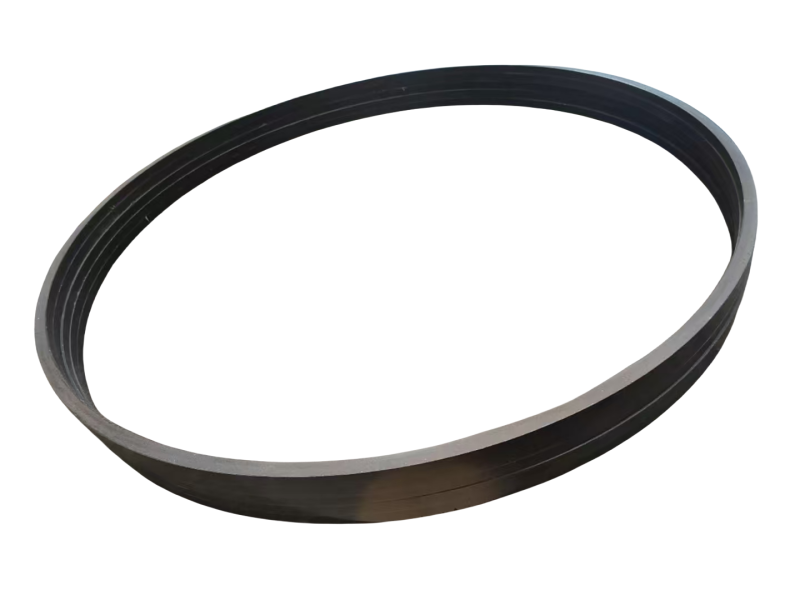

Valve Seats, Valve sealings, valve components,washers,discs and gasket are the important components in Valves. The low friction and corrosion resistance of PTFE make it widely used in high-end valves.

Virgin PTFE offers extreme resistance to electrical insulation and thermal stability.,Teflon(PTFE) can be used in a a variety of applications having a combination of mechanical, electrical, chemical, temperature and anti-friction properties that are unmatched. PTFE has a very high melting point and is capable of continued service at 500F (260 C). It is the most chemically resistant plastic available and only a few chemicals react with it. PTFE mechanical properties are low compared to other engineering plastics, but its integrity is maintained over a wide temperature range - from -400 to 500°F (-240 to 260°C). Mechanical properties can be improved by the addition of fillers such as glass fiber, carbon, graphite, molybdenum disulfide and bronze. PTFE has excellent thermal and electrical insulation properties along with a low coefficient of friction.

| Property | PTFE | PTFE (25% glass filled) | PTFE (25% carbon filled) | PTFE(25% Graphite filled) | PTFE(25% Bronze filled) | Expanded PTFE |

| Density (g/cm³) | 2.13 | 2.25 | 2.09 | 2.16 | 3.9 | 0.8-0.9 |

| Water Absorption, 24 hrs (%) | < 0.01 | <0.01 | <0.01 | < 0.01 | 0.02 | |

| Tensile Strength (Mpa) | 35 | 21 | ≥13 | 21 | 13.8 | ≥10mpa |

| Elongation at Break (%) | 250 - 400 | 205 | 92 | 100 | 101 | |

| Flexural Strength (Mpa) | 22.5 | 13.4 | 15.8 | 12 | ||

| Compressive Strength | 23 | 15 | 16 | 16 | 12 | ≤140mpa |

| Hardness, Shore D | 57 | 58 - 64 | 75 - 85 | 59 - 62 | 62 - 67 | |

| Shrinkage rate % | 3 | 2.1 | 1.8-2.8 | 1.8-2.8 | ||

| Friction Coefficient | 0.1 | 0.15-0.17 | 0.16-0.18 | 0.16-0.18 | 0.18-0.2 | |

| Work Temperature ( °C) | -180~260℃ | -180~260℃ | -180~260℃ | -180~260℃ | -180~260℃ | -240~270℃ |

| Flammability Rating | V-O | V-O | V-O | V-O | V-O | |

| Application | Diaphragms & Electrical ,General Chemical Use | Bearings , Valve Seats,Gaskets,Seals,Compressor rings | Seats & Valve Seats | Slide ring | electrical connectors | flanges seal |

| Properties summary | FDA compliant | Increases compressible strength, rigidity and wear. Reduces creep and cold flow Minimal effect on chemical and electrical properties |

Increases compressible strength, hardness, wear, and load properties. Good chemical resistance Various types and amounts of carbon can be added to alter conductivity |

Reduces coefficient of friction Reduces initial wear Increases strength |

Increases hardness and wear resistance Increases dimensional stability and compressive strength Not suitable for corrosive or electrical applications |